KOMBAT ENERGY LIMITED

TECHNOLOGY

Most biodiesel production technologies use transesterification reaction and are based on outdated, tank technologies, which have been proven to be inefficient and costly. Kombat Energy limited is looking to deploy a high-frequency magnetic impulse cavitation principle.

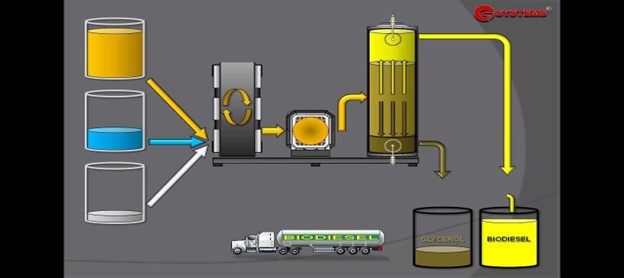

The system consists of methanol, oil and catalyst tanks, a group of feed pumps for each stream, Coriolis flowmeters, two reactors, separation tank, product tanks, electrical units and a Programmable Logic Control (PLC) system.

The process of transesterification converts 88% – 90% of feedstock into biodiesel with the remaining 10% forming crude glycerol. The different components separate out by gravity in a separation tank. The equipment is designed with a 20-year lifespan.

Advantages Of Technology

Low demands on the quality of the raw oil

High-frequency magnetic impulse cavitation processors work successfully and steadily with both raw and purified oil, and with all types of animal fats and fat mixtures with vegetable oils. This wide range of oils (shea butter, sunflower oil, rapeseed oil, linseed oil, palm oil, mustard oil etc.) can be used for biodiesel fuel production with almost any acid number and it is also possible to use waste from livestock and poultry processing plants. The equipment does not need to be adjusted when the type of oil is changed.

“One pass” reaction procedure

Unlike in outdated “tank” technologies, no re-etherification reaction is needed in magnetic impulse cavitation technology. This innovation means that the time taken to obtain biodiesel is reduced by a factor of 8-10.

Purifying sorbates, washing and drying are not required

When using conventional technologies, it is not possible to obtain proper quality biodiesel fuel immediately. Therefore, a process of impurity elimination, involving washing or purifying using sorbates, is needed. This requires additional equipment for primary biodiesel product washing (a mixture of water and alcohol is usually used for this purpose) and additional units for what is known as vacuum drying. When the cavitation biodiesel manufacture method is used there is no need for the finished product to be washed or dried, and this therefore eliminates waste water and sorbate utilization processes.

Minimal alcohol and catalyst quantity. No alcohol recovery process

One of the main problems with “tank” technologies is the need to add, and consequently to recover, additional methanol to the processor. This requires additional equipment and wastes electric power. In cavitation technology, the alcohol quantity used for the reaction conforms precisely to the stochiometric composition, i.e. the minimum volume.

There is no need for a re-esterification reaction. The use of expensive and dangerous equipment for methanol recuperation is excluded from the process. Any inevitable alcohol losses during recovery are eliminated, which improves the environmental conditions and explosion-proof characteristics.

Minimum energy consumption

Conventional biodiesel production methods are based on heating the oil to 67-70 °C. This involves significant electric power costs; in addition, the methanol recovery process (required when the reaction is carried out using conventional technologies), additional re-esterification and also vacuum dehydrating lead to considerable electric power consumption. The use of cavitation processing eliminates all the stages mentioned above, which means that 5-7 times less electric power is used.

Low-temperature reaction

In high-frequency magnetic impulse cavitation, processing takes place in the processor on molecular level. All components are exposed to magnetic-directed cavitation pulses. Fatty acid molecules are split using micro-explosions; this results in a decrease of viscosity, a cetane number increase, an improvement in the energetic parameters of the future fuel and a considerable acceleration and improvement of the etherification reaction quality. It must be noted that the reaction takes place at room temperature and there is no need to heat the oil.